Featured Project

Connect with what we do through a hands-on project.

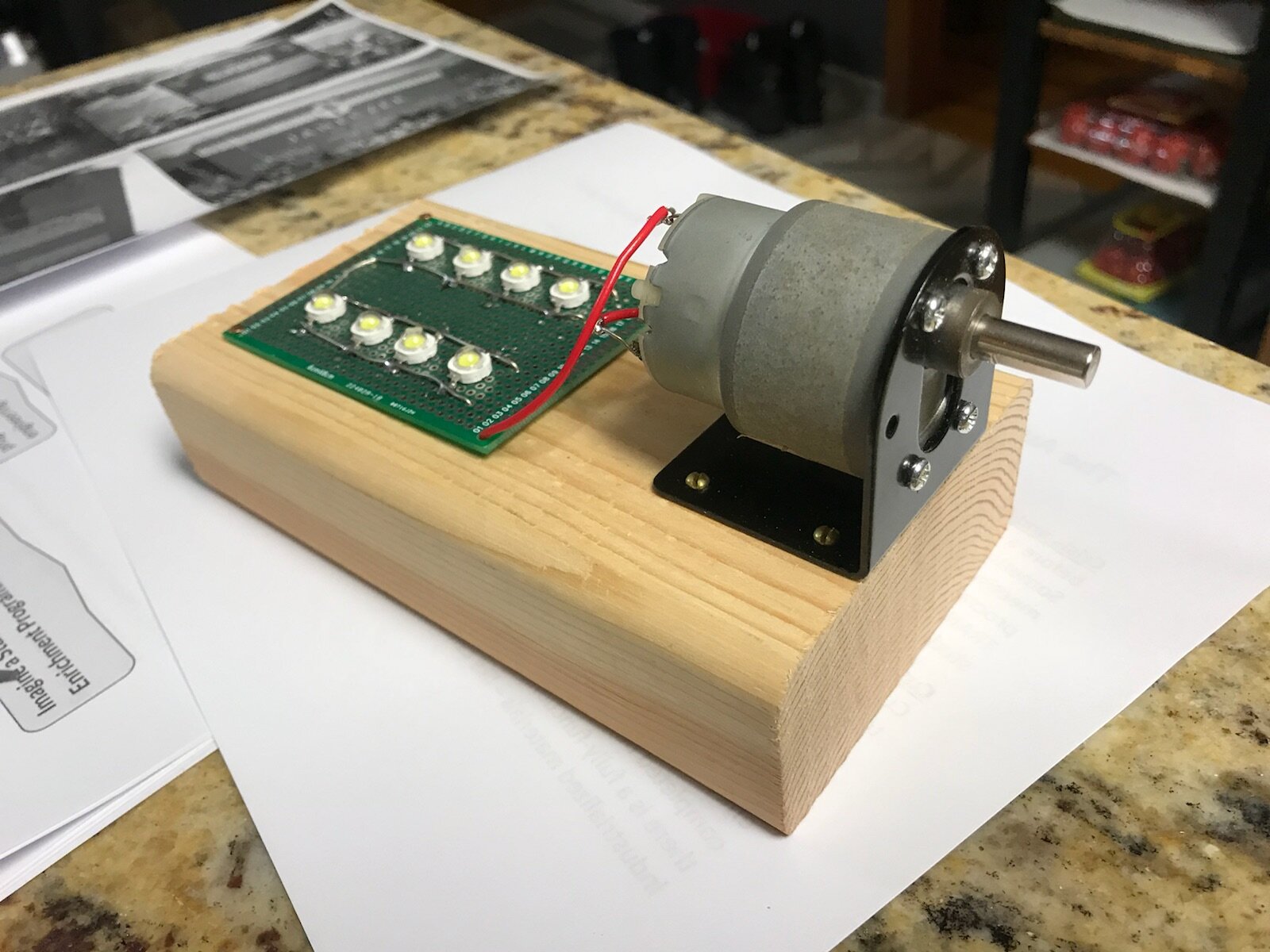

Windmill Generator Demonstration

Imagine being tasked with building a windmill electrical energy generator for a large and well-known nature conservancy – and the Chief Engineer is 11 years old! That’s Sam, Chief Engineer, and who worked hands-on to evaluate and select the motor/generator, aligned, assembled, and painted the windmill blades, and prepared and soldered over 200 electrical connections for a sign that illuminates with the energy produced by his windmill! A good kid who is willing to try, Sam tackled one problem after another – each adding to his skills and confidence. This is “learning by doing” and with our guidance, Sam is realizing his potential step-by-step. And THAT is what it is all about!

See Sam’s finished Windmill featured on the Duke Farms Instagram! https://www.instagram.com/reel/CUIy29OLqLG/?utm_medium=copy_link

“I’m really proud of what we created.”

— Samuel Kang, Project Participant

Project Highlights

Many opportunities for Sam to learn by doing.

Cultivating mechanical and electrical skills.

Fostering independent work and decision-making.

Developing record-keeping and reporting skills.

Teamwork through planning and division of labor.

Collaborating with a professional engineer in another country and time zone.

Transforming from uncertain of his actions to BRIMMING WITH EARNED CONFIDENCE!

Project Progression

All of our projects start with a kickoff meeting, which is the first of several planned meetings intended to ensure the team is clear on the project’s goals and plans. These times are also excellent for knowledge sharing and collaborative problem solving. In Sam’s case the kickoff meeting was international with a colleague located in Asia!

Early on in the project, the team needed to identify the best components for the windmill. This stage provided the student participant (Samuel) with the opportunity to learn about power generation through hands-on work.

Interesting note… Samuel’s parents recently overheard him likening a fight between two friends as two electrons repelling each other.

Most of the parts needed to be assembled or manufactured from raw materials. Participation in these processes helped Samuel build new skills and also understand what goes into the products we use and enjoy.

One of the project’s first milestones was the assembly of the windmill. It was extremely exciting for Samuel to not only see the pieces come together but to also assemble the windmill himself.

After assembling the windmill, the team turned the lights off and generated some wind via a fan. The video below recorded the inaugural run of the windmill. The team was excited to see that the windmill was able to power the test set of LEDs.

After verifying the windmill was functional and able to generate power for the test LEDs, the team moved on to making sure it could generate enough power for the full set of LEDs. The team experienced another great win when the windmill was able to power all of the LEDs under natural wind.

Sam presented his Windmill to the Nature Conservancy’s Education Team to great applause!!! Sam clearly and concisely articulate the overall function of the Windmill and energy generation process as well as pointed out all of his hands-on project work! Sam’s presentation was a part of a energy-generation educational training offered by Main Engine Start. Sam’s Windmill is now a on-site demonstration for the visiting Public!

Sam started this project a bit uncertain, and ended it BRIMMING WITH EARNED CONFIDENCE!! That is what Main Engine Start is all about!!!