“Authentic Engineering Experience” (AEE) is a project-based-learning challenge that tasks individuals or small Teams of 2 to 4 students to solve a real problem for a real customer in one semester. All project activity is hands-on and “live” – without classroom lectures or Labs. Principles and skills are experienced first-hand. The student Team members are treated as Professional Engineers– not as students. The focus is for the student team to learn by doing. The practical objectives are to expose students, early in their careers to methods and techniques used in industry and give students authentic hands-on product development and teamwork experience to relate to potential internship and professional employers.

The concept of the Authentic Engineering Experience (AEE) was created by MES Founder Dr Peter Stupak while he was still in industry. He implemented AEE while an Associate Professor of Engineering and Physics at Raritan Valley Community College (RVCC), running over 30 project Teams involving over 90 students over a period of 6 years.

Please see our Current and Past AEE projects below!!!!!

May 10, 2023 Pinoccio’s Nose II!! Safran and Torres: Theatrical Synergy at Its Best

In the world of amateur theater, there is a certain magic that shines from the stage when an unexpected twist of creativity comes to life. Such was the case with Will Safran's delightful performance as Pinocchio in Shrek the Musical at The Play Group Theatre in White Plains, NY on May 10.

In a beautifully serendipitous turn of events, Safran's mother, Gerrie, happened upon a press release about a Pinocchio nose created by RVCC Engineering student Jimena Torres for the same musical the year before. This chance encounter led to a successful collaboration between Safran and Torres. Safran, in need of the iconic extendable nose for his role, and Torres, with her engineering prowess and first-hand experience, joined forces to bring the unmistakable character to life.

Torres generously shared her technical expertise, 3D designs, and guidance on the size and mechanism for the nose. With the support of nonprofit Main Engine Start, the elements were 3D printed, laying the groundwork for the physical embodiment of the puppet-turned-real-boy.

But Safran added his own creativity to the design by implementing an alternative mechanism to control the extension and retraction of the nose. Powered by a battery-operated linear actuator, the device provided an element of surprise that both caught the audience off guard and evoked hearty laughter.

This story of the Pinocchio nose is a shining example of the power of collaboration and creativity. It is a tale of how the meeting of minds and sharing of expertise can lead to a theatrical marvel. A nose by any other name might not have made such an impact, but this particular nose was a triumph of collaborative creativity.

Photo by Alex Lynford

Water Quality Test-Tube Washer!

RVCC Students, Bernard Babitsky, Melissa Armenta-Quiroz, and Mauricio Rios, along with Project Manager Liam Boyle, were tasked by RVCC Professor of Environmental Science, Emilie Stander, to create a novel semi-automated/fully automated Water-Quality-Sample-Tube “Washer”. Dr. Stander conducts environmental research at the College to assess the level of watershed contaminants that find their way into local streams and rivers. Accurate testing of chemical levels requires super-clean water-gathering equipment, and sample “tubes” are a critical link in the chain! To prevent waste, the tubes are currently cleaned by hand through a multi-step “wash-by-hand” process that removes sediment and trace chemical contaminants, allowing the tubes to be reused multiple times. However, the “wash-by-hand” process is long and time consuming! The AEE Team developed an 8-tube washing device and process that passed the Lab Technician’s critical review!

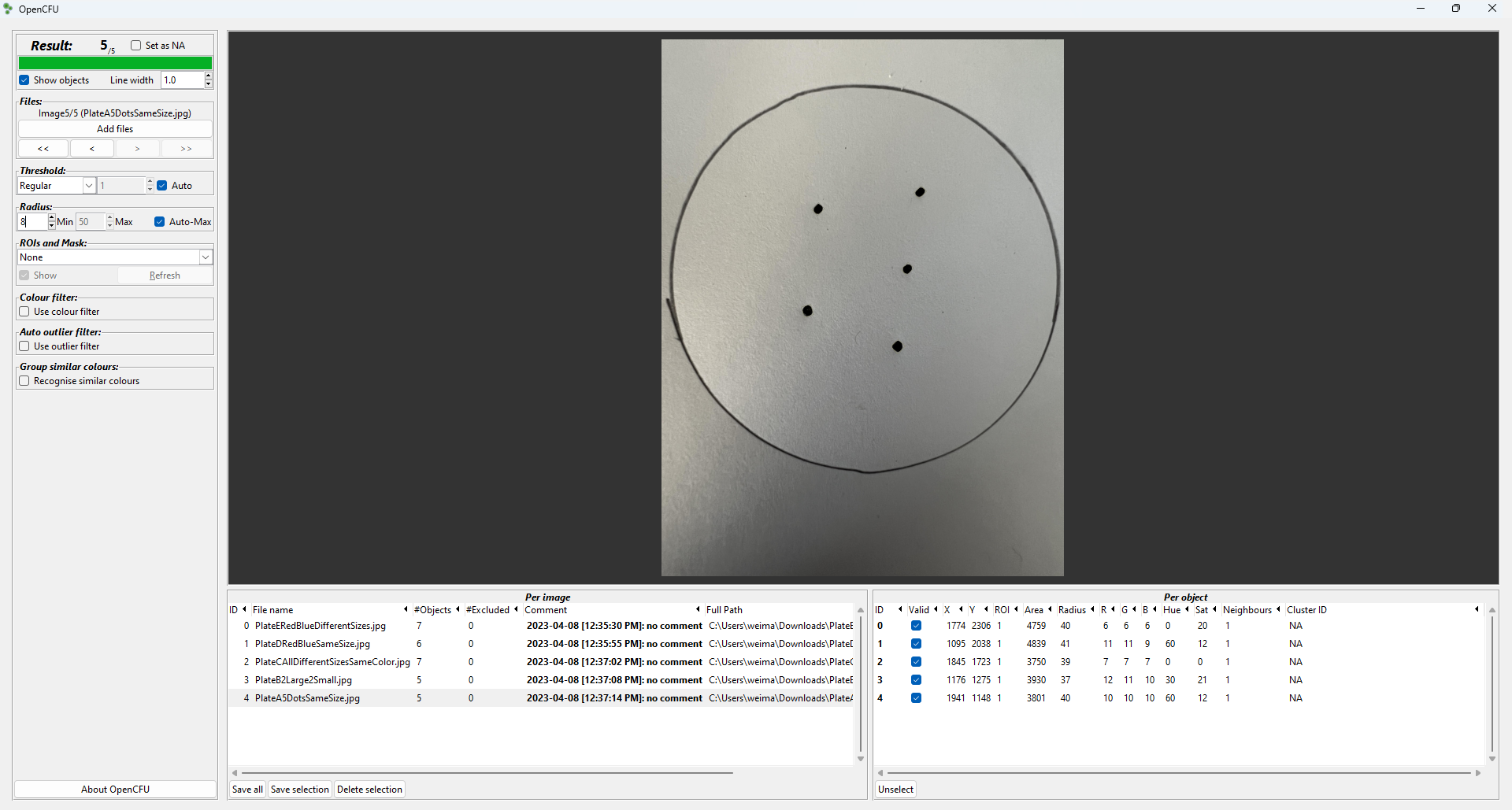

Bacteria Image Analysis!

RVCC Students, Matthew Wei, along with Project Manager Liam Boyle, were tasked by RVCC Professor of Environmental Science, Emilie Stander, to develop an automated image analysis that can count bacterial colonies resulting from Water Quality Testing samples. The water taken from streams, rivers, and ponds is deposited on biological growth media to provide an environment for bacterial growth. To quantify the bacterial concentration in the water sample, the bacterial colonies have been historically counted manually - but this is a long and tedious process. Matthew made progress to develop an automated image analysis and counting system. Difficulties in consistently identifying the bacterial colonies and distinguishing the red/blue bacteria type difference will result in the project being extended to Fall 2023.

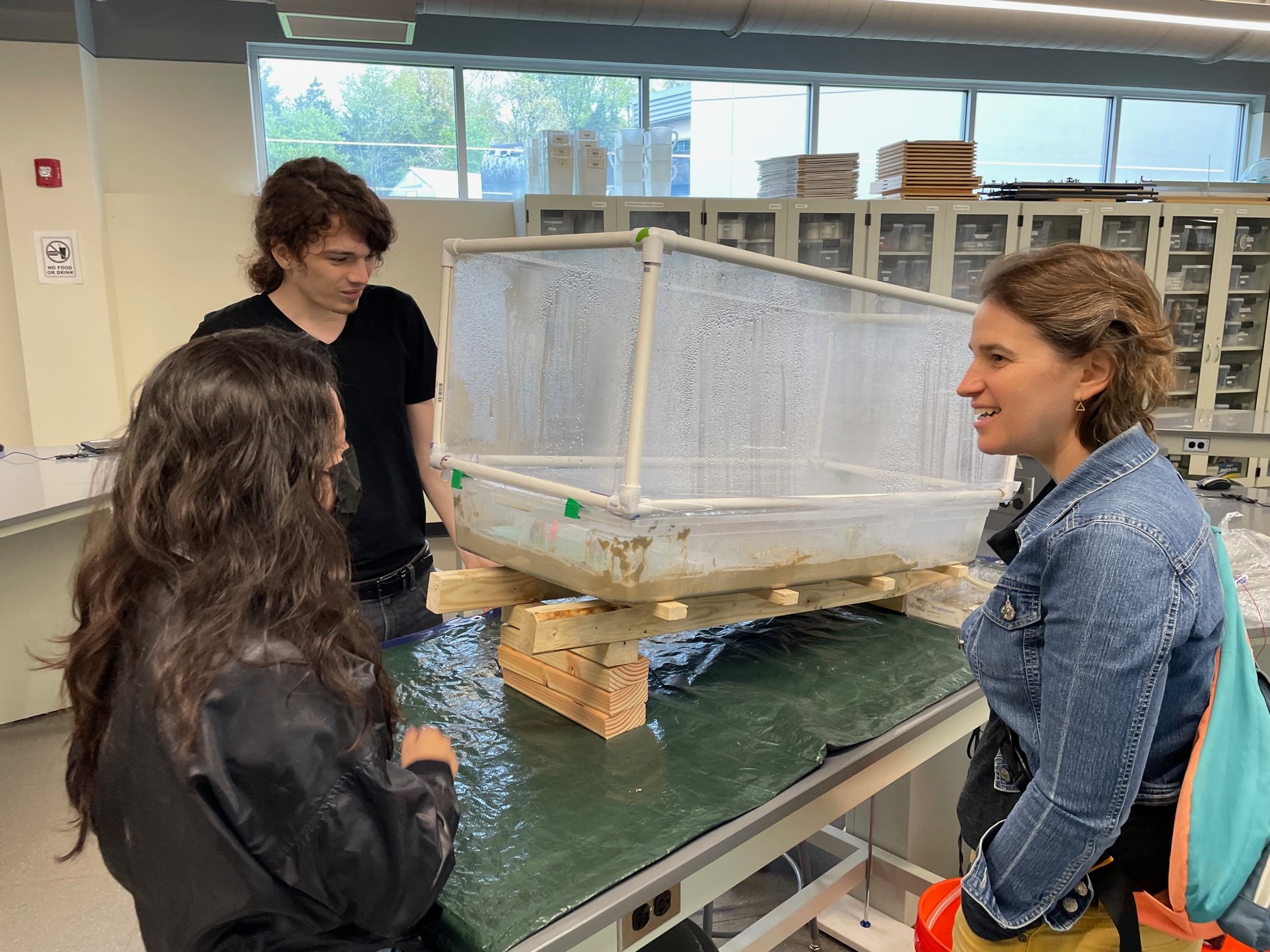

Watershed Demonstration Table!!!

RVCC Students, Madeleyn Andrade Cajamarca and Oliver Tenny, were tasked by Artist Lauren Rosenthal McManus to design, develop, and fabricate a fully functional prototype of a “Watershed Table” that allows time-lapse video to be taken of watershed erosion phenomena resulting from Climate Change induced increase rainfall rates. Features including permeable (e.g., sand and soil) and impermeable surfaces (e.g., parking lots), vegetation, trees, slope angle, and rain fall rates and quantity were included. The time-lapse video will be used to inform and educate decision makers and the public.

Art Illumination (Part 2) - Industrialization!!

RVCC Students, Aashitha Srinivas and Lavern Ronoh, were tasked by RVCC Professor of Graphic Design, Darren McManus, to “Industrialize” the fully functional prototype made by the previous Teams (Part 1). Lavern designed and made prototypes of the required circuit during the 2022 summer and Fall semester. Aashitha is working in Spring 2023 to replicate the circuit, complete the design and assembly of the display unit, and assume full responsibility for the completion of six Art Illumination units that will be used in Professor McManus’ Exhibition in Spring 2024.

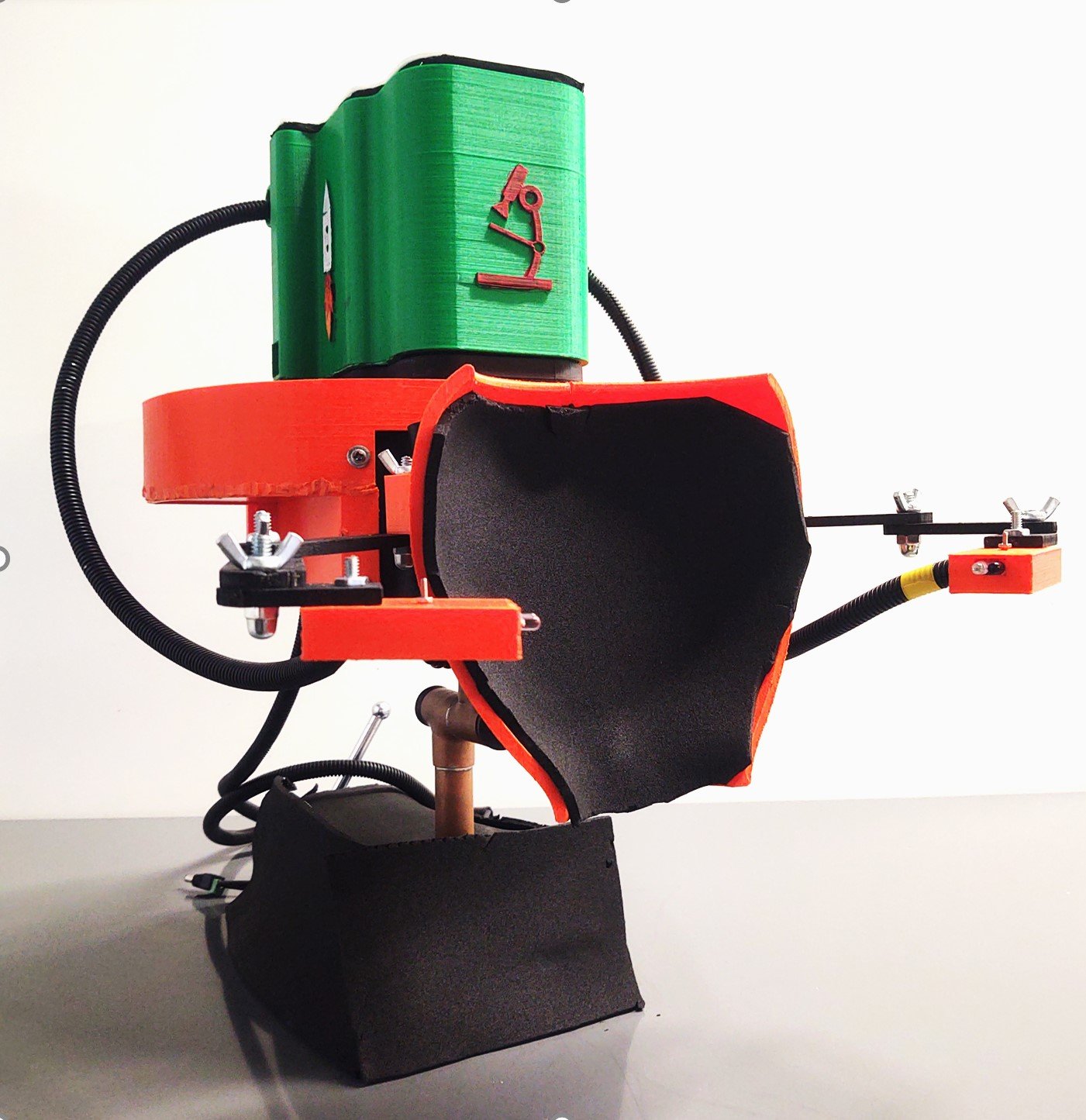

Power Assisted Rotating Head Support - Part 3!!

RVCC Students, Ahmad Insanally, Mahmoud Mohamed, Marcelo Rios, and Project Manager Kyle Hammermueller, “Industrialized” the “Power Assisted Rotating Head Support” to make it ready to mount to a wheelchair and be tested in service!! Some key “industrialization” points were: protecting and isolating the device mechanical gears, motor, and electronics in a protective case, reduce the motor noise, develop a battery-power level circuit, and improve the “Ear Control” switch sensitivity by using a new light-activated proximity switch.

Art Illumination (Part 1) - Fully Functional Prototype!!

RVCC Students, Joseph DeNisco, Thomas Hayes, and Agustin Osses Falco, were tasked with designing, developing, and fabricating a fully functional prototype of a “green energy” “light box” that would illuminate translucent artistic sculptures placed on the top of the box. This request came from RVCC Graphic Design Professor, Darren McManus. The “Green Energy” component was that Professor McManus wanted that all energy came from the Viewer interacting with the piece and that no batteries or wall-plug power connections were to be used. Thomas started the project in Fall 2021 and created an initial prototype where the electrical energy was made by the user turning a hand-crank that rotated a DC motor generator. Joseph and Agustin continued the project in Spring 2022 and refined the hand-crank design and completed the fully functional prototype.

·Rotating Head Support Part 1:

Engineering and Graphic Design students collaborated to design and fabricate a wheelchair-mounted rotating head support for a local disabled child. The rotating head support overcame the limitations of commercial fixed head supports and allowed the child to rotate his head sufficiently to more frequently activate mechanical switches, located near his head, and thereby interact with educational software. The Graphic Design students also provided input for a more “kid-friendly” aesthetic and created complete product “visual identities” and branding campaigns. The project was then formalized in Spring 2022 in a technical paper and one of the students involved presented the Rotating Head Support project, on behalf of their teammates, at the American Society for Engineering Education (ASEE) Mid-Atlantic Conference, held April 22-23 at NJIT. The technical paper was published in the Conference Proceedings - https://peer.asee.org/engineering-and-graphic-design-interdisciplinary-collaborative-product-development-a-wheelchair-mounted-rotating-head-support-for-a-disabled-child (Note: This project was started when MES Founder Peter Stupak was a faculty member at RVCC).

Power Assisted Rotating Head Support Part 2:

In May 2022, the Director of Occupational Therapy at a local hospital for disabled children contacted MES and asked if the original Rotating Head Support (Part 1) could be motorized to help more of their disabled children. A Team of three students, Liam Boyle, Kyle Hammermueller, and Kasen Groth, worked on this project from June 2022 and to January 2023, when they presented their fully-functional prototype to the Customer and received excellent praise and feedback! The fully functional prototype included, a micro-controller (Arduino), a servo-motor to powered the drive-gear rotation, and switches located inside the head-support allowing the child to activate the rotation by slightly tilting their head. The frame, gears, and pads of the head support were designed using 3D Design software and made using a 3D Printer. The smooth operation of the system was achieved using a PID controller.

Green Energy Golf Cart:

The Green Energy Golf Cart was made by RVCC Biology Major, Anusha Srinivas, an avid golfer, and who has a strong interest in engineering. Through the project Anusha made innovative design changes to a hand-pulled golf cart to generate sustainable “green electrical energy” that could be used to charge a cell-phone battery, as well as cool a beverage when a player is on the golf course. Anusha used the rotational energy from one of the golf cart wheels to turn a DC motor that performed as an electrical generator to charge her phone. Additionally, she used a solar panel to generate electricity to operate a thermoelectric cooler that becomes cold on one side to cool the beverage and warm on the opposite side. A heat-sink and small fans were used to efficiently vent the excess heat back into the environment. All the components were designed using 3D Design software and made using a 3D Printer.

Anusha presented her Green Energy Golf Cart project at the American Society for Engineering Education (ASEE) Northeast Section 2021 Annual Conference, held October 21-23 at Worcester Polytechnic Institute in Massachusetts, were she won 1st Place as the “Best Student Paper” at the conference. Her work was published in the Conference Proceedings - http://asee-ne.org/conferences/aseene/2021/index.php/aseene/aseene2021/paper/view/33

Viewpoint LIDAR Object Detection:

A local hospital for disabled children requested a device that attaches to a wheelchair to allow a 13 year old vision-impared girl to navigate a hallway at the hospital that may contain obstacles (e.g., a chair). RVCC Biology student, Adwaita Bhagwat, used a scanning LIDAR system that projects a laser light into the hallway and records the reflection times (distance) and angle to locate objects in the hallway. The LIDAR system was a commercial system that student controlled using an Arduino microcontroller. Also, the student added a stepper motor to allow the laser to scan vertically to create a 3D view of the hallway. Buzzers were used to indicate if an object was present on the left or the right within a defined distance and angle range.

Pinocchio’s Nose:

RVCC Engineering student, Jimena Torres, performed the part of Pinocchio in the SpotLight Players theater rendition of “Shrek The Musical” that ran July 22-24 and July 29-31, 2022 at the First Presbyterian Church of Matawan. Jimena took on the task of designing and fabricating a “Pinocchio Nose” that would extend and contract during the performance of the Play. She used 3D Design software and 3D printing to fabricate the “Nose” elements and the mask to which the nose connects. To extend and contract the “Nose”. Jimena used a bicycle shifter-cable and sheath and attached one end to the inside tip of the “Nose” and the other end to a custom 3D designed and printed “Slider” that attached to the belt of her costume. By subtly moving the “Slider” with her hand, she was able to make the “Pinocchio Nose” extend and contract to the delight of the audience!!

Catalyst Compactor:

A University of Maryland Engineering student, Sarah Cornet, succeeded in developing a a fully-functioning prototype to automatically and consistently compact catalyst particles for use in a chemical reactor as needed by a local business. Solenoids, controlled by an “Arduino Microcontroller”, were used to “Tap” the sides of the chemical reactor and the resulting vibrations compacted the catalyst particles within the reactor. Sarah conducted all of the hands-on prototyping, electronic circuit assembly and testing, and microprocessor programming to make the prototype function.